-

Plasma underwater

-

Guillotine scissors

Options

The processing of stainless steel is carried out in our plant in Hückelhoven-Baal near Düsseldorf. Therefore it is possible for NiRo to have all standard sizes in stock and to produce all non standard sizes or special types fast and with high quality.

Welding

MIG (metal inert gas)

MAG (metal active gas)

Plasma arc welding

Processing

Sheet metal cutting

Guillotine scissors max. 3000 x 10 mm

Saw cutting

Rollers

Thicknesses up to max. 30 mm (depending on length)

Edge

up to 20 mm thickness

Coming soon: 3d-tube laser 12 kW

-

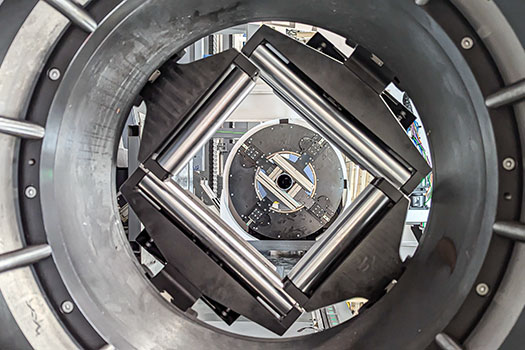

3d tube laser

-

chuck

Why pickle stainless steel?

Stainless steel forms a passive layer with a chromium content of >12%, which protects the material and makes it corrosion-resistant. Contaminants, foreign rust and, above all, weld seams and their oxide layers destroy this passive layer, meaning there is no protection against external media such as moisture.

In addition to grinding and brushing, pickling is a cost-effective way of removing these contaminants. During pickling, material in the µm range is removed, creating a metallically pure surface. On this surface, the chromium reacts with oxygen from the atmosphere to form a new passive layer. This effect is achieved directly after pickling by additional passivation.

After 25 years of constant use of pickling agents (hydrofluoric acid and nitric acid), it was time for a new immersion pickling tank. A steel core, which is completely covered with PE, creates a container that holds 35 m³ of pickling agent. With a size of 8 m x 2.5 m x 2 m, it is also possible to pickle large containers or pipes. In addition to our ongoing production, we also offer contract pickling. Thanks to constant modernization and monitoring, our pickling plant is always up to date.